Microstructure analysis has emerged as a revolutionary approach in fiber science, enabling researchers and manufacturers to unlock unprecedented levels of material performance and functionality.

🔬 The Foundation of Fiber Microstructure Science

Understanding fiber microstructure requires delving into the intricate world of molecular arrangements, crystallinity patterns, and morphological features that exist at microscopic and nanoscopic scales. These structural characteristics fundamentally determine how fibers behave under various conditions, from mechanical stress to environmental exposure.

The microstructure of a fiber encompasses several critical elements: the orientation of polymer chains, the degree of crystallinity versus amorphous regions, void spaces, surface topology, and the distribution of any additives or reinforcing agents. Each of these components plays a vital role in defining the final properties of the fiber, whether it’s used in textile applications, composite materials, or advanced technical fabrics.

Modern analytical techniques have transformed our ability to visualize and quantify these structural features. Scanning electron microscopy (SEM), transmission electron microscopy (TEM), atomic force microscopy (AFM), and X-ray diffraction methods provide unprecedented insights into fiber architecture. These tools allow scientists to observe structural features ranging from nanometers to micrometers, creating a comprehensive picture of material organization.

⚡ How Microstructure Influences Fiber Performance

The relationship between microstructure and performance is neither simple nor linear. Multiple structural parameters interact synergistically to produce the macroscopic properties that determine a fiber’s suitability for specific applications. Understanding these relationships is essential for optimizing fiber design and manufacturing processes.

Mechanical Properties and Structural Alignment

Tensile strength, elongation, and modulus are directly influenced by polymer chain orientation and crystallinity. When polymer chains align parallel to the fiber axis, they create stronger intermolecular forces and more efficient load transfer mechanisms. High-performance fibers like aramids and ultra-high molecular weight polyethylene achieve their remarkable strength through exceptional molecular alignment achieved during processing.

The crystalline regions within fibers act as physical cross-links, providing structural rigidity and resistance to deformation. However, amorphous regions contribute flexibility and toughness. The optimal balance between these phases depends on the intended application, and microstructure analysis helps engineers fine-tune this balance with precision.

Durability and Environmental Resistance

Microstructural features significantly impact how fibers withstand environmental challenges such as UV radiation, chemical exposure, moisture, and temperature fluctuations. Dense, highly ordered structures typically provide better barrier properties, limiting the penetration of degrading agents. Conversely, more open structures may facilitate moisture transport, which can be advantageous in certain applications like sportswear but detrimental in others.

Surface morphology, observable through microstructure analysis, influences adhesion properties, friction characteristics, and susceptibility to soil accumulation. Fibers with smooth, compact surfaces generally exhibit better stain resistance, while rougher surfaces may provide enhanced grip or bonding capabilities in composite applications.

🎯 Advanced Techniques in Microstructure Characterization

The evolution of analytical instrumentation has paralleled advances in fiber science, providing increasingly sophisticated tools for microstructure investigation. These techniques offer complementary information, and comprehensive characterization typically requires multiple analytical approaches.

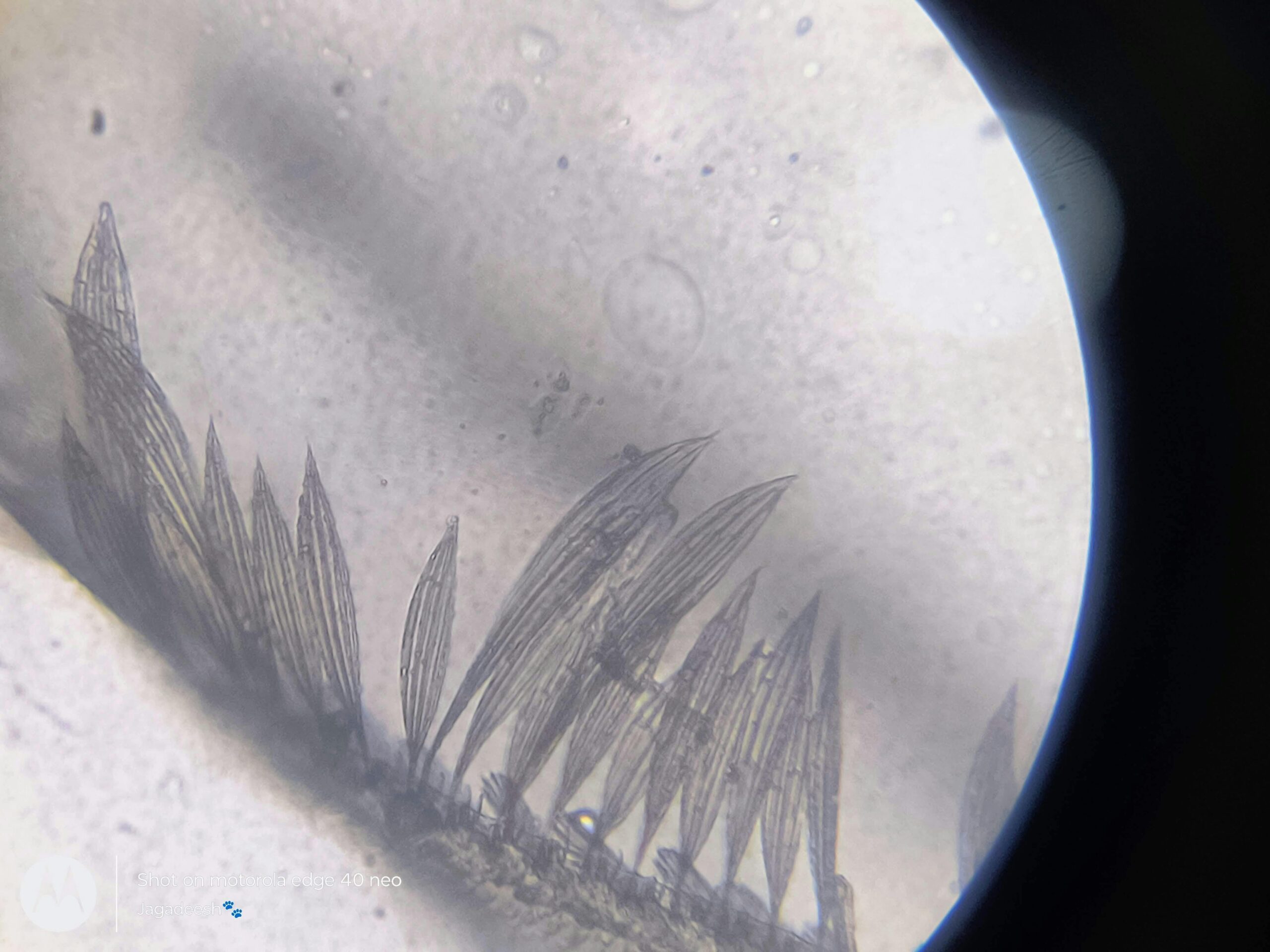

Microscopy-Based Methods

Electron microscopy remains the gold standard for visualizing fiber microstructure. SEM provides detailed surface topography and cross-sectional information, revealing features like skin-core morphology, void distribution, and surface defects. Modern SEM instruments equipped with field emission sources achieve resolutions below one nanometer, enabling observation of individual nanofibers within composite structures.

TEM penetrates deeper into understanding internal structure, revealing crystalline lamellae, fibrillar arrangements, and phase separation in polymer blends. Specialized techniques like cryo-TEM preserve native structures without artifacts from sample preparation, particularly valuable for studying moisture-sensitive or temperature-sensitive materials.

AFM brings unique capabilities to fiber analysis by providing three-dimensional topographical maps with nanometer resolution while measuring mechanical properties at the nanoscale. This technique can map variations in stiffness across a fiber’s cross-section, identifying distinct phases and their distribution.

Diffraction and Spectroscopic Approaches

X-ray diffraction techniques provide quantitative information about crystallinity, crystal orientation, and crystal structure. Wide-angle X-ray scattering (WAXS) identifies crystalline phases and measures their degree of orientation, while small-angle X-ray scattering (SAXS) reveals larger-scale structural features like lamellar spacing and void sizes.

Spectroscopic methods including infrared and Raman spectroscopy identify chemical composition and molecular interactions. These techniques can map chemical variations across fiber cross-sections, detecting surface treatments, additives, or degradation products. Raman microscopy, in particular, combines chemical identification with spatial resolution, creating chemical maps of heterogeneous fiber structures.

🏭 Transforming Manufacturing Through Microstructure Control

Understanding microstructure fundamentals enables manufacturers to engineer fibers with precisely tailored properties. This transformation from empirical trial-and-error approaches to knowledge-based design represents a paradigm shift in fiber production, dramatically reducing development time and improving product consistency.

Process-Structure Relationships

Every step in fiber manufacturing influences microstructure development. Polymer synthesis determines molecular weight distribution and chain architecture. Spinning conditions—including temperature profiles, draw ratios, and cooling rates—control crystallization kinetics and molecular orientation. Post-spinning treatments like heat-setting, stretching, or annealing further modify structure.

By correlating processing parameters with resulting microstructures, manufacturers create process maps that predict outcomes. Real-time monitoring systems increasingly incorporate microstructure-sensitive measurements, enabling adaptive process control that maintains optimal conditions despite variations in raw materials or environmental factors.

Innovative Processing Techniques

Advanced manufacturing methods leverage microstructure principles to achieve previously impossible property combinations. Electrospinning creates nanofibers with extraordinarily high surface-to-volume ratios and unique microstructures suited for filtration, medical scaffolds, and protective membranes. The technique’s ability to control fiber diameter, orientation, and porosity at nanoscale opens new application frontiers.

Melt-blown and spunbond processes produce nonwoven fabrics with carefully engineered microstructures optimized for specific performance metrics. Bicomponent spinning creates fibers with designed cross-sectional architectures—core-sheath, side-by-side, or islands-in-sea configurations—each delivering unique functional properties derived from their microstructural design.

💡 Application-Specific Microstructure Optimization

Different applications demand different microstructural characteristics, and advanced analysis enables precise tailoring for each use case. The following examples illustrate how microstructure understanding translates into performance advantages across diverse sectors.

High-Performance Technical Textiles

Ballistic protection materials require fibers with maximum energy absorption capabilities. Microstructure analysis reveals that highly oriented, extended-chain structures with minimal defects provide optimal performance. Manufacturing processes are designed to maximize chain alignment while minimizing structural discontinuities that could serve as failure initiation sites.

Firefighter protective gear demands thermal insulation combined with moisture management. Microstructure engineering creates fibers with controlled porosity and layered structures that provide thermal barriers while allowing vapor transport. Analysis techniques verify that these complex structures maintain their architecture through repeated laundering and exposure cycles.

Medical and Hygiene Applications

Surgical sutures benefit from microstructures that provide initial strength for wound closure while allowing controlled degradation as healing progresses. Bioabsorbable polymers are engineered with specific crystallinity levels and molecular orientations that determine both mechanical performance and degradation kinetics. Microstructure analysis confirms that these properties remain within specifications throughout shelf life and sterilization processes.

Absorbent materials in hygiene products require microstructures with high porosity and specific surface chemistries. Analysis guides the creation of fiber networks that rapidly wick moisture away from skin while distributing fluids throughout the product. Surface modifications visible through microstructure techniques enhance liquid-solid interactions without compromising mechanical integrity.

Smart and Functional Fibers

Conductive fibers for wearable electronics integrate metallic or carbon-based materials within polymer matrices. Microstructure analysis reveals the distribution and connectivity of conductive phases, directly correlating with electrical performance. Engineers use this information to optimize processing conditions that maintain conductivity while preserving textile-like mechanical properties and washability.

Shape-memory fibers exhibit programmable deformation behaviors determined by their microstructural characteristics. The balance between crystalline and amorphous phases, along with molecular orientation, controls transition temperatures and recovery forces. Detailed microstructure characterization enables design of fibers that respond predictably to temperature, moisture, or pH changes.

🌍 Sustainability Through Microstructure Innovation

Environmental concerns increasingly drive fiber development, and microstructure analysis plays a crucial role in creating sustainable materials. Understanding structure-property relationships enables design of bio-based and recycled fibers that match or exceed petroleum-derived counterparts in performance.

Bio-based polymers often exhibit different crystallization behaviors and morphologies compared to conventional synthetics. Microstructure analysis identifies processing modifications needed to optimize these alternative materials. For instance, polylactic acid (PLA) fibers achieve improved performance when processing conditions enhance crystallinity and molecular orientation based on insights from structural characterization.

Recycled fibers face challenges from degradation during reprocessing. Microstructure examination reveals chain scission, reduced molecular weight, and increased defect density. This knowledge guides development of compatibilizers, stabilizers, and process modifications that restore performance. Advanced analysis demonstrates that properly optimized recycled fibers can achieve microstructures comparable to virgin materials.

Durability improvements driven by microstructure optimization reduce resource consumption by extending product lifespans. Fibers engineered for enhanced resistance to UV degradation, hydrolysis, or mechanical fatigue require replacement less frequently, reducing environmental impact across their lifecycle.

📊 Data Integration and Predictive Modeling

Modern approaches combine microstructure analysis with computational methods, creating powerful predictive capabilities that accelerate innovation. Machine learning algorithms trained on extensive datasets of structure-property correlations can predict fiber performance from microstructural parameters or suggest processing conditions to achieve target properties.

Finite element modeling incorporates microstructural details to simulate fiber behavior under complex loading conditions. These virtual experiments reduce reliance on physical prototyping, saving time and resources during development. Models continuously improve as validation against real microstructure data refines their accuracy.

Digital twin technologies create virtual replicas of manufacturing processes, incorporating microstructure evolution at each stage. These systems enable scenario testing, process optimization, and quality prediction before implementing changes on production lines. Real-time microstructure monitoring feeds back into digital twins, creating adaptive systems that maintain optimal performance.

🚀 Future Horizons in Microstructure-Driven Fiber Technology

Emerging techniques promise even deeper insights into fiber microstructure. In-situ characterization methods observe structural changes as they occur during processing or performance testing, revealing transient phenomena invisible to post-mortem analysis. These real-time observations accelerate understanding of structure development mechanisms.

Multi-scale modeling frameworks integrate information from molecular simulations through microstructure characteristics to macroscopic properties. This hierarchical approach connects chemistry with engineering performance, enabling truly rational material design. As computational power increases and algorithms improve, these models will become increasingly predictive and accessible.

Artificial intelligence applications extend beyond prediction to autonomous optimization. AI systems could continuously adjust processing parameters to maintain optimal microstructures despite raw material variations or equipment drift. Eventually, these systems might even suggest novel fiber architectures beyond human intuition, designed specifically for emerging applications.

🎓 Bridging Research and Industrial Implementation

Despite remarkable advances in microstructure analysis capabilities, a gap often exists between academic research and industrial practice. Laboratory techniques providing exquisite detail may be too slow, expensive, or specialized for routine quality control. Bridging this gap requires developing simplified analytical protocols that capture essential microstructural information with practical speed and cost.

Portable or online analytical instruments increasingly bring sophisticated characterization to production environments. Rapid optical methods, miniaturized spectroscopy systems, and automated image analysis provide microstructure-relevant data in real-time, enabling process adjustments that maintain quality without interrupting production.

Training programs ensure that workforce capabilities keep pace with technological advances. Understanding microstructure principles empowers operators, technicians, and engineers to interpret analytical data meaningfully and make informed decisions. This knowledge transfer multiplies the impact of advanced characterization investments.

✨ Realizing the Full Potential of Microstructure Mastery

The journey from understanding basic fiber microstructure to implementing knowledge-driven manufacturing represents a fundamental transformation in how the industry approaches material development. Success requires integration of advanced analytical capabilities, process expertise, computational tools, and clear application focus.

Organizations that invest in microstructure analysis capabilities position themselves to respond rapidly to emerging market demands, troubleshoot quality issues efficiently, and innovate with confidence. The competitive advantages extend beyond individual products to encompass accelerated development cycles, reduced waste, and enhanced sustainability credentials.

As analytical techniques continue advancing and becoming more accessible, microstructure-driven design will transition from specialized expertise to standard practice. The fibers of tomorrow will be engineered with atomic-level precision to deliver exactly the performance profile each application demands, made possible by unlocking the power of microstructure analysis.

This transformation is already underway across the fiber industry, from commodity textile production to advanced technical fibers. Whether improving comfort in everyday clothing, enhancing safety in protective equipment, or enabling breakthrough technologies in medical devices and electronics, microstructure analysis provides the foundation for continuous innovation and optimization that defines modern fiber science.

Toni Santos is a textile systems researcher and sustainable materials strategist specializing in the study of circular design frameworks, waste-stream innovation, and the transformation of fiber lifecycles. Through an interdisciplinary and material-focused lens, Toni investigates how the fashion and textile industries can regenerate resources, eliminate pollution, and embed sustainability into production systems — across supply chains, processes, and material cultures. His work is grounded in a fascination with fibers not only as materials, but as carriers of environmental impact. From dye-waste reduction techniques to regenerative textiles and closed-loop manufacturing, Toni uncovers the material and systemic tools through which industries can preserve resources and restore their relationship with ecological balance. With a background in design systems and fiber transformation science, Toni blends material analysis with supply-chain research to reveal how textiles can be used to shape circularity, reduce waste, and encode sustainable innovation. As the creative mind behind Nuvtrox, Toni curates circular design models, regenerative fiber studies, and material interpretations that revive the essential ties between textiles, ecology, and responsible production science. His work is a tribute to: The transformative potential of Circular Design Modeling Practices The critical innovation of Dye-Waste Reduction and Clean Processing The regenerative science of Fiber Transformation Research The systemic accountability of Supply-Chain Sustainability and Traceability Whether you're a sustainable materials innovator, circular economy researcher, or curious explorer of regenerative textile systems, Toni invites you to discover the future of fiber stewardship — one thread, one loop, one system at a time.