Modern supply chains demand precision, accountability, and real-time visibility. Traceability technologies have emerged as essential tools for businesses seeking to optimize operations and build consumer trust.

🔍 The Growing Imperative for Supply Chain Visibility

In today’s interconnected global marketplace, companies face unprecedented pressure to demonstrate transparency across their entire value chain. Consumers increasingly demand to know where their products come from, how they’re manufactured, and whether ethical standards were maintained throughout the process. Simultaneously, regulatory bodies worldwide are implementing stricter compliance requirements, making traceability not just a competitive advantage but a fundamental business necessity.

Traditional tracking methods—paper-based documentation, manual record-keeping, and fragmented data systems—have proven inadequate for meeting these evolving demands. These legacy approaches create information silos, increase the risk of errors, and leave businesses vulnerable to counterfeiting, recalls, and supply chain disruptions. The solution lies in leveraging advanced traceability technologies that provide end-to-end visibility, data integrity, and seamless information sharing.

📡 RFID Technology: The Foundation of Automated Tracking

Radio-Frequency Identification (RFID) represents one of the most mature and widely adopted traceability technologies available today. Unlike traditional barcodes that require line-of-sight scanning, RFID tags use electromagnetic fields to automatically identify and track objects equipped with these small electronic devices. This capability has revolutionized inventory management across industries ranging from retail and logistics to healthcare and manufacturing.

How RFID Systems Operate

An RFID system consists of three primary components: tags, readers, and a backend database. Tags contain a microchip and antenna that store unique identification data. When an RFID reader emits radio waves, nearby tags respond by transmitting their stored information back to the reader. This data is then processed and integrated into enterprise resource planning (ERP) or warehouse management systems (WMS), providing real-time visibility into asset locations and movement.

RFID technology comes in two main varieties: passive and active tags. Passive tags draw power from the reader’s electromagnetic field and are cost-effective for high-volume applications like retail merchandise tracking. Active tags contain their own power source, enabling longer read ranges and continuous broadcasting—ideal for tracking high-value assets or monitoring environmental conditions during transit.

Real-World Applications Driving ROI

Major retailers have implemented RFID to achieve inventory accuracy rates exceeding 95%, dramatically reducing stockouts and overstock situations. In the pharmaceutical industry, RFID enables serialization and track-and-trace capabilities that combat counterfeit medications and ensure regulatory compliance. Manufacturing facilities use RFID to track work-in-progress inventory, optimize production workflows, and implement just-in-time delivery systems that minimize carrying costs.

The aviation sector has embraced RFID for baggage tracking, significantly reducing lost luggage incidents while improving operational efficiency at airports worldwide. Healthcare providers utilize RFID to track medical equipment, manage pharmaceutical inventory, and even monitor patient movements within facilities to enhance safety protocols.

🔗 Blockchain: Establishing Immutable Trust Networks

While RFID excels at capturing and transmitting data, blockchain technology addresses a different but equally critical challenge: ensuring that recorded information remains tamper-proof and transparent across multiple stakeholders. Blockchain creates a distributed ledger system where transaction records are cryptographically secured and replicated across network participants, eliminating the possibility of unilateral data manipulation.

The Architecture of Transparency

A blockchain consists of sequential blocks containing timestamped transaction data, cryptographic hashes, and links to previous blocks. When a new transaction occurs, network participants (nodes) validate it through consensus mechanisms before permanently adding it to the chain. This decentralized verification process ensures that no single entity can alter historical records without detection, creating an immutable audit trail.

Smart contracts—self-executing programs stored on blockchain networks—further enhance traceability applications by automating compliance verification and triggering actions when predetermined conditions are met. For example, a smart contract could automatically release payment when RFID sensors confirm that a refrigerated shipment maintained proper temperature throughout transit.

Transforming Supply Chain Trust

Food and beverage companies leverage blockchain to provide farm-to-fork traceability, allowing consumers to verify the origin, certifications, and journey of products by scanning a simple code. When contamination issues arise, blockchain-enabled systems can identify affected batches within seconds rather than days, dramatically reducing recall scope and protecting consumer safety.

The diamond and luxury goods industries employ blockchain to combat counterfeiting by creating digital certificates of authenticity that follow products throughout their lifecycle. Fashion brands are using blockchain to verify sustainable sourcing claims, responding to environmentally conscious consumers who demand proof of ethical production practices.

International shipping and logistics companies are implementing blockchain platforms that digitize documentation, reduce paperwork delays, and provide all stakeholders with synchronized visibility into shipment status. This approach eliminates redundant data entry, reduces disputes, and accelerates customs clearance processes.

📱 QR Codes: Democratizing Consumer Engagement

Quick Response (QR) codes have evolved from simple marketing tools into sophisticated traceability interfaces that bridge the gap between physical products and digital information. These two-dimensional barcodes can store significantly more data than traditional linear barcodes while remaining cost-effective to implement at scale. Their ubiquity and smartphone compatibility make QR codes particularly valuable for consumer-facing traceability applications.

Beyond Basic Product Information

Modern QR code implementations go far beyond displaying basic product specifications. When integrated with backend traceability systems, scanning a QR code can reveal comprehensive provenance information, including manufacturing location, ingredient sourcing, quality certifications, environmental impact data, and detailed handling instructions.

Dynamic QR codes take this capability further by linking to URLs whose content can be updated without changing the printed code itself. This flexibility allows manufacturers to provide real-time information, respond to emerging issues, and even personalize content based on scanning location or user preferences.

Empowering Informed Consumer Decisions

The COVID-19 pandemic accelerated QR code adoption for contactless interactions, and consumers have grown increasingly comfortable using their smartphones to access product information. Progressive brands recognize this shift as an opportunity to build deeper customer relationships through transparency.

Wine producers use QR codes to share vineyard histories, harvest conditions, and winemaking techniques—transforming each bottle into an educational experience. Cosmetics companies provide ingredient transparency and allergen warnings through QR-accessible databases. Electronics manufacturers offer detailed recycling instructions and take-back program information to support circular economy initiatives.

In regulated industries like pharmaceuticals, QR codes on packaging enable patients to verify medication authenticity, access proper usage instructions in multiple languages, and report adverse reactions directly to manufacturers or regulatory agencies.

⚙️ Integration Strategies for Maximum Impact

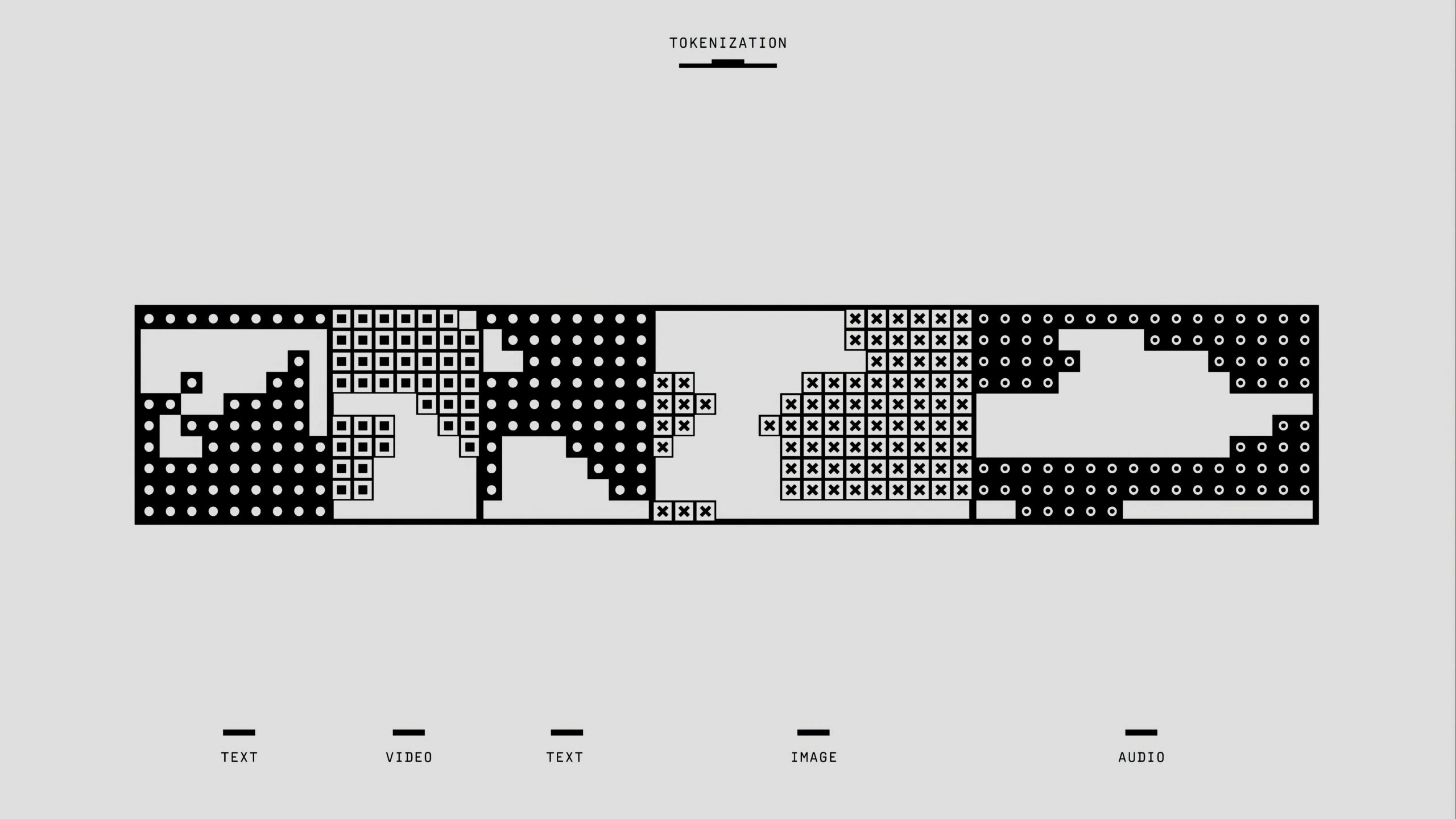

While each traceability technology offers distinct advantages, their true potential emerges when implemented as complementary components of an integrated system. The most effective traceability solutions combine multiple technologies to address different requirements across the supply chain journey.

Layered Technology Approaches

A comprehensive traceability architecture might use RFID for automated warehouse operations, blockchain for multi-party transaction verification, and QR codes for consumer engagement. This layered approach ensures that data capture occurs automatically where possible, recorded information remains tamper-proof, and end customers can easily access relevant details.

Consider a pharmaceutical supply chain: RFID tags track medication containers through manufacturing and distribution facilities, providing real-time inventory visibility and preventing diversion. Blockchain records each custody transfer and verifies cold chain compliance through integrated temperature sensors. Finally, QR codes on consumer packaging enable patients to confirm authenticity and access usage information while allowing pharmacies to efficiently process dispensing records.

Overcoming Implementation Challenges

Successfully deploying traceability technologies requires careful planning and stakeholder alignment. Organizations must assess their specific needs, existing infrastructure, and industry requirements before selecting appropriate solutions. Common implementation challenges include:

- Interoperability concerns: Ensuring different systems and technologies can communicate effectively across organizational boundaries

- Data standardization: Adopting common data formats and identification schemes that facilitate information exchange

- Change management: Training personnel and adjusting workflows to leverage new capabilities effectively

- Scalability considerations: Selecting solutions that can grow with business needs without requiring complete replacement

- Cost-benefit analysis: Justifying initial investments through quantifiable operational improvements and risk reduction

- Privacy and security: Implementing appropriate safeguards to protect sensitive commercial and personal information

Pilot programs offer valuable opportunities to test technologies on a limited scale, identify integration issues, and demonstrate return on investment before committing to enterprise-wide deployment. Starting with high-value use cases—such as tracking expensive inventory or meeting specific regulatory requirements—helps build organizational support and generates funding for broader initiatives.

📊 Measuring Success: Key Performance Indicators

Implementing traceability technologies represents a significant investment, and organizations must establish clear metrics to evaluate effectiveness and justify continued development. The following table outlines critical performance indicators across different operational dimensions:

| Performance Area | Key Metrics | Target Improvements |

|---|---|---|

| Inventory Accuracy | Cycle count precision, stock-out frequency | 95%+ accuracy, 50% reduction in stock-outs |

| Operational Efficiency | Processing time, labor hours, error rates | 30-40% faster processing, 60% fewer errors |

| Supply Chain Visibility | Real-time tracking coverage, data latency | End-to-end visibility, sub-minute updates |

| Compliance | Audit preparation time, violation incidents | 80% faster audits, zero compliance failures |

| Customer Satisfaction | Transparency requests fulfilled, trust scores | Complete product histories, improved NPS |

Beyond these quantitative measures, organizations should also track qualitative benefits such as enhanced brand reputation, improved supplier relationships, and increased organizational agility in responding to market changes or disruptions.

🌍 Industry-Specific Applications Driving Innovation

Different sectors face unique traceability challenges that drive specialized applications of these technologies. Understanding industry-specific use cases provides valuable insights for organizations considering implementation.

Food and Agriculture

The food industry faces intense pressure to prevent contamination outbreaks, verify organic and sustainability claims, and provide consumers with origin information. Integrated traceability systems track products from farm to fork, recording harvest dates, processing facilities, storage conditions, and distribution channels. When issues arise, these systems enable surgical recalls that remove only affected products rather than entire categories, minimizing economic impact and protecting brand reputation.

Healthcare and Pharmaceuticals

Patient safety depends on maintaining proper custody and condition of medications and medical devices throughout the supply chain. Traceability technologies combat counterfeit drugs, ensure proper storage conditions, and enable efficient recall management. Hospitals use these systems to track high-value equipment, manage expiring inventory, and maintain regulatory compliance documentation.

Manufacturing and Electronics

Complex products containing hundreds of components require detailed traceability for quality control, warranty management, and regulatory compliance. Manufacturers track component origins, assembly processes, and quality test results, creating comprehensive product genealogies that support root cause analysis when defects occur. This granular visibility also facilitates circular economy initiatives by enabling efficient product disassembly and component recovery at end-of-life.

🚀 Emerging Trends Shaping the Future

Traceability technologies continue evolving rapidly, with several emerging trends promising to further enhance capabilities and expand applications.

Artificial Intelligence and Machine Learning

AI algorithms analyze traceability data to identify patterns, predict potential disruptions, and recommend optimization opportunities. Machine learning models can detect anomalies indicating counterfeit products, forecast demand based on real-time inventory movements, and optimize routing decisions by analyzing historical performance data.

Internet of Things Integration

Combining traceability technologies with IoT sensors creates intelligent supply chains that monitor product condition continuously. Temperature, humidity, shock, and light exposure data captured by integrated sensors provides proof of proper handling and enables proactive intervention before products deteriorate.

Augmented Reality Enhancement

AR applications overlay digital traceability information onto physical products viewed through smartphone cameras, creating intuitive interfaces for warehouse workers, quality inspectors, and consumers. These immersive experiences make complex supply chain data accessible to non-technical users.

💡 Building a Roadmap for Implementation Success

Organizations embarking on traceability initiatives should follow a structured approach that aligns technology investments with strategic business objectives. Begin by conducting a comprehensive assessment of current capabilities, pain points, and regulatory requirements. Engage stakeholders across functions—operations, IT, quality, compliance, and commercial teams—to ensure solutions address genuine business needs rather than implementing technology for its own sake.

Develop a phased implementation plan that delivers quick wins while building toward long-term transformation. Start with contained use cases that demonstrate clear ROI, then expand incrementally as organizational capabilities mature. Prioritize interoperability and standards compliance to avoid creating new data silos that undermine transparency objectives.

Invest in change management and training programs that help personnel understand not just how to use new technologies, but why traceability matters for organizational success and their individual roles. Celebrate successes publicly to build momentum and secure ongoing executive support.

Partner with experienced technology providers who understand industry-specific requirements and can provide implementation support, ongoing maintenance, and future capability enhancements. Evaluate potential partners based not only on technical capabilities but also on their commitment to open standards and ecosystem collaboration.

🎯 Capturing Competitive Advantage Through Transparency

Forward-thinking organizations recognize that traceability technologies represent far more than compliance tools or operational efficiency enablers. These systems create strategic assets that differentiate brands, build customer loyalty, and unlock new business models. Companies that provide superior transparency attract increasingly discerning consumers while gaining resilience against supply chain disruptions.

The journey toward comprehensive traceability requires vision, investment, and organizational commitment. However, the benefits—operational excellence, regulatory confidence, enhanced reputation, and consumer trust—far outweigh the challenges. As technologies mature and ecosystem standards develop, traceability will transition from competitive advantage to table stakes, making early adoption increasingly valuable.

Organizations that embrace RFID, blockchain, QR codes, and emerging traceability technologies position themselves not merely to survive but to thrive in an increasingly transparent, accountable, and connected global marketplace. The question is no longer whether to implement these capabilities, but how quickly you can transform your operations to meet rising stakeholder expectations.

Toni Santos is a textile systems researcher and sustainable materials strategist specializing in the study of circular design frameworks, waste-stream innovation, and the transformation of fiber lifecycles. Through an interdisciplinary and material-focused lens, Toni investigates how the fashion and textile industries can regenerate resources, eliminate pollution, and embed sustainability into production systems — across supply chains, processes, and material cultures. His work is grounded in a fascination with fibers not only as materials, but as carriers of environmental impact. From dye-waste reduction techniques to regenerative textiles and closed-loop manufacturing, Toni uncovers the material and systemic tools through which industries can preserve resources and restore their relationship with ecological balance. With a background in design systems and fiber transformation science, Toni blends material analysis with supply-chain research to reveal how textiles can be used to shape circularity, reduce waste, and encode sustainable innovation. As the creative mind behind Nuvtrox, Toni curates circular design models, regenerative fiber studies, and material interpretations that revive the essential ties between textiles, ecology, and responsible production science. His work is a tribute to: The transformative potential of Circular Design Modeling Practices The critical innovation of Dye-Waste Reduction and Clean Processing The regenerative science of Fiber Transformation Research The systemic accountability of Supply-Chain Sustainability and Traceability Whether you're a sustainable materials innovator, circular economy researcher, or curious explorer of regenerative textile systems, Toni invites you to discover the future of fiber stewardship — one thread, one loop, one system at a time.